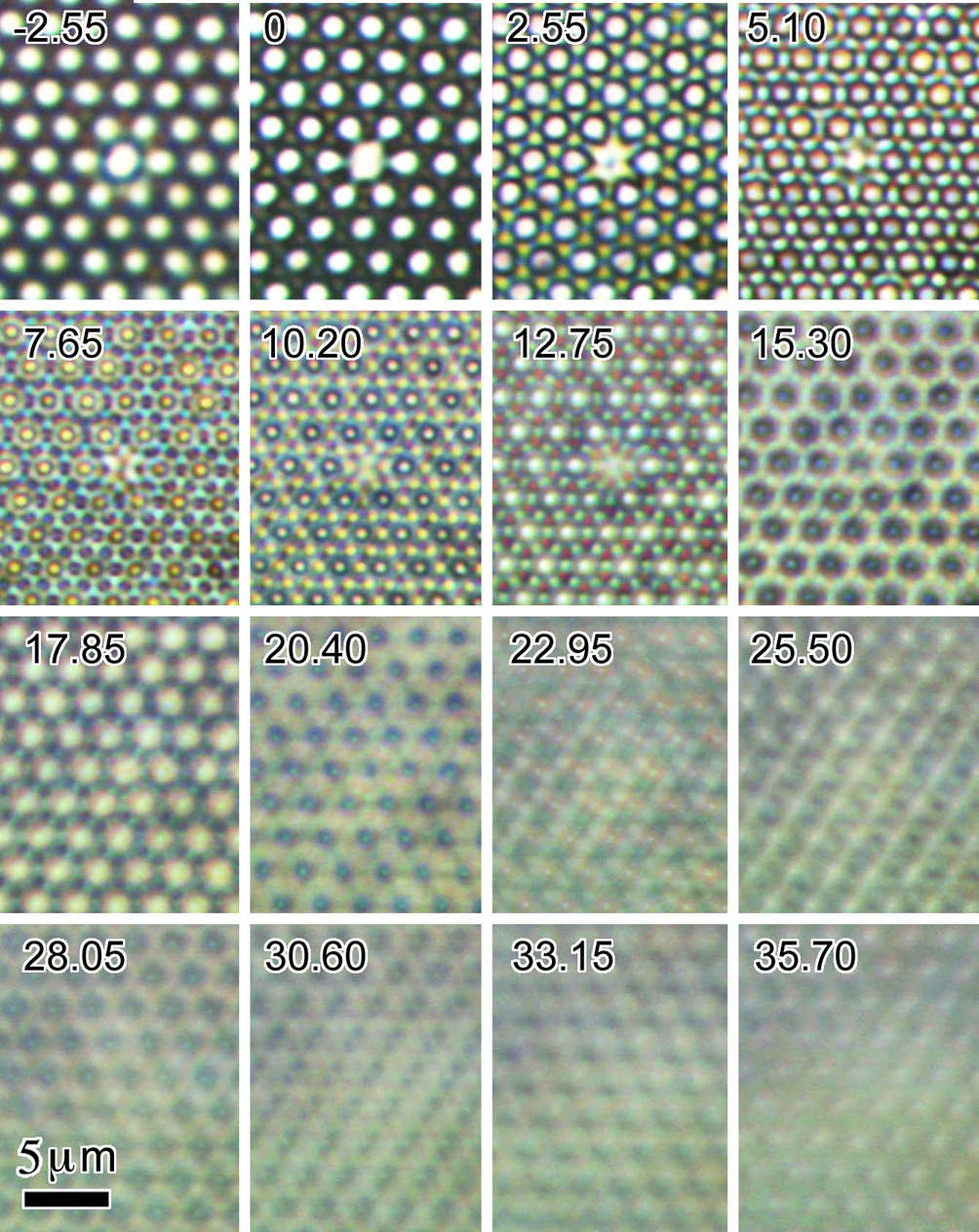

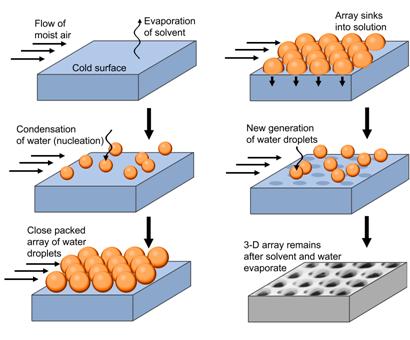

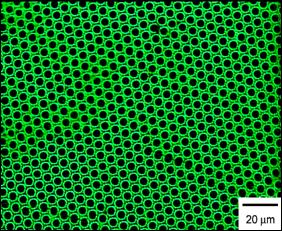

Srinivasrao et al (Science, 292 (5514): 79 APR 6 2001) reported the formation of a three dimensionally ordered array of air bubbles of monodisperse pore size in a polymer film through a templating mechanism unlike most published in the literature. Dilute solutions of a simple, coil-like polymer in a volatile solvent are cast on a glass slide in the presence of moist air flowing across the surface. Evaporative cooling, and the generation of an ordered array of breath figures, forms multilayers of hexagonally packed water droplets that are preserved in the final, solid polymer film as spherical air bubbles. The dimensions of these bubbles can be simply controlled by changing the velocity of the airflow across the surface. Such three dimensionally ordered macroporous materials with dimensions comparable to visible light are predicted to have unique optical properties such as photonic band-gaps, and optical stop-bands.

The ordered array is imaged by using three dimensional image reconstruction using the confocal microscope. The 3D structure can be obtained in conducting polymers by using dilute solutions of conjugated polymers in just a matter of few minutes. Lulu "Bubble" Song creates bubbles in a variety of polymers, and is investigating various aspects and applications of these macroporous structures